Replacement Extruder Control Panel

Ageing Panels

Many plastic extruders are 20 to 30 + years old are mechanically sound and work well but have control panels with a DC drive that is showing its age. Some panel control components like the field control are inefficient and crude. In this picture (see Image) the field instead of being controlled with a thyristor bridge has a transformer and external field failure circuit, all components have no easy replacement. In Series with the DC armature circuit is positioned an overload device to give additional overload protection for the DC motor.

`

Replacement Panel

A modern drive like a Parker SSD (Ex Eurotherm) or Sprint Drive includes these features built in which enable the whole panel to be simplified. This was recently done with a Windmöller & Hölscher DC drive control panel. The Siemens 6RA series DC drive was removed and a Parker SSD drive fitted with many of the features built in enabling the removal of a lot of the electrical switchgear. The improved diagnostic functions reduces machine downtime and increases the reliability. In the new picture electrical shrouding is still required to cover exposed live conductors.

Why not choose AC?

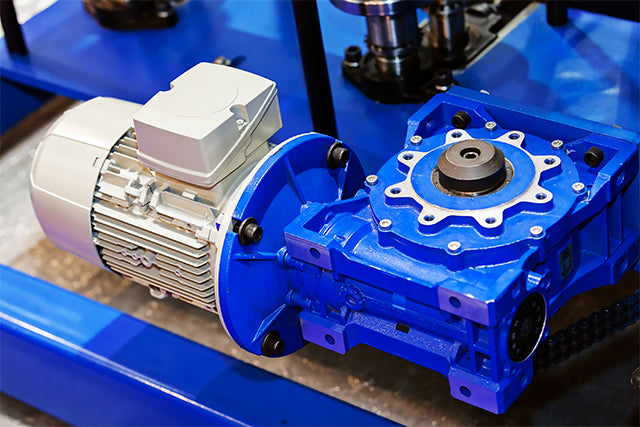

New plastic extruders generally come with AC motors and inverter drives instead of the traditional DC system set up. AC motors require less maintenance and have a better power factor when used with a 3 phase inverter. It is common instead of repairing a DC motor is to have it replaced with a AC motor and inverter. Depending on the application and Extruder type a replacement AC motor can be used without the use of an encoder. Encoders give the added benefit of closed loop vector control with very accurate speed holding of 0.1%.

DC motors come with a Tachogenerator which Typically have a speed holding of approximate 1%. A customer after having the DC motor fail and repaired twice in 6 months decided to opt for an AC motor replacement with an inverter drive to be installed instead of the DC drive and motor system. The motor needs to hold constant torque down to zero speed. This is not a problem with a force ventilation fan fitted instead of a standard impeller for motor cooling. The old DC drive and motor shown in the pictures below and the new replacement AC motor and inverter drive shown. The plastic extruder was run and tested with the new AC setup and meters calibrated. If space for a larger AC motor is a problem we can choose a compact square frame design which will be as small as a DC motor of the same Kw rating.