2.2kW - 132kW - Water Pump Panel

Powerful and Adaptable Water Pump Control

2.2kW - 132kW - Water Pump Panel

Product Code: PBC-001-2-2

In stock

£1,790.60 - £5,474.80

£1,790.60

Next Working Day Delivery* Please allow an extra working day for Scottish Highlands, Northern Ireland, Channel Islands and Isle of Man (Carriage may be extra for these areas).

Please Note:

To suit our international customers, all prices are displayed ex-VAT. Taxes will be added at Checkout.

Next Working Day Delivery is affected by bank holidays,

More Info.

Have a question?

Powerful and Adaptable Water Pump Control

in a Compact Footprint: The Fuji Pump Panel

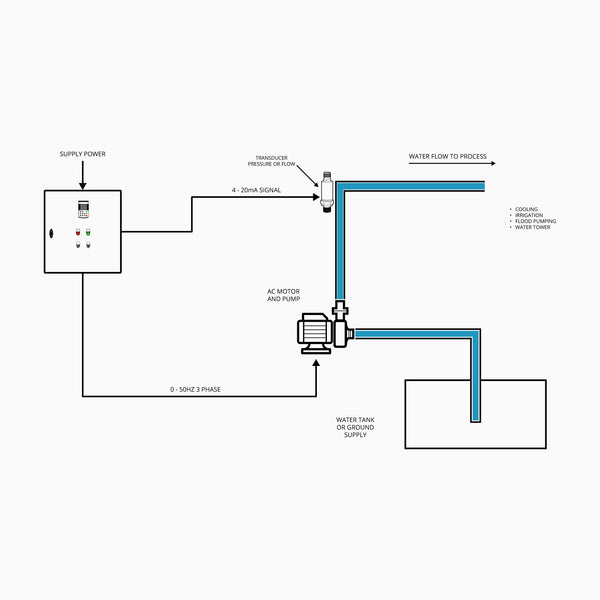

Water Pump Inverter Drive Panels

The Fuji Pump Panel is designed to streamline and optimize the operation of various water pumps, from centrifugal and positive displacement models to irrigation, borehole, cooling tower, and flood water pumps, all within a space-saving design. Its user-friendly interface and compact dimensions (Please see table dimensions) ensure both simplicity and effectiveness, catering to both basic and complex pumping needs in tight spaces.

Key Features:

-

Dual Operation Modes:

- Manual:Control pump speed directly with the door-mounted potentiometer for straightforward water flow at a set rate.Reduce speed for pressure control or energy saving.

- Automatic:Set a desired pressure via the keypad,and the internal PID loop automatically adjusts pump speed to maintain it.Fine-tune response with adjustable gains.

-

Versatile Applications:

- Maintain constant water levels in reservoirs or tanks using a 4-20mA level sensor.

- Adapt to diverse pumping needs with customizable configurations.

-

Safety and Protection:

- Door-interlocked isolator safeguards against electrical hazards.

- High-speed fuses provide fault protection.

- IP54 rating for splash resistance.

-

Advanced Functionality:

- Dedicated Fuji Water pump V-F quadratic curve settings.

- High-performance,energy-saving Fuji inverter with built-in EMC filter.

- 4-20mA input feedback for real-time data on pressure,flow,or other process variables.

-

Enhanced User Experience:

- Door-mounted keypad for programming,displaying motor diagnostics,and setting pressure in automatic mode.

- External remote start/stop button option for added convenience.

-

Customization Options:

- Integrate an additional output choke or filter for extended motor cable runs.

- Discuss specific needs with our team for tailored solutions.

Dimensions

| SKU | kW | Amps | Height (mm) | Width (mm) | Depth (mm) |

|---|---|---|---|---|---|

| PBC-001-2-2 | 2.2 | - | 600 | 400 | 250 |

| PBC-001-5-5 | 5.5 | - | 600 | 400 | 250 |

| PBC-002-11 | 11 | - | 600 | 600 | 300 |

| PBC-002-15 | 15 | - | 600 | 600 | 300 |

| PBC-003-18-5 | 18.5 | - | 800 | 600 | 400 |

| PBC-003-22 | 22 | - | 800 | 600 | 400 |

| PBC-004-30 | 30 | - | 1000 | 600 | 400 |

| PBC-004-37 | 37 | - | 1000 | 600 | 400 |

| PBC-005-45 | 45 | - | 1000 | 800 | 400 |

| PBC-005-55 | 55 | - | 1000 | 800 | 400 |

| PBC-006-75 | 75 | - | TBC | TBC | TBC |

| PBC-006-90 | 90 | - | TBC | TBC | TBC |

| PBC-007-110 | 110 | - | TBC | TBC | TBC |

| PBC-007-132 | 132 | - | TBC | TBC | TBC |

USEFUL DOWNLOADS

FRENIC-ACE Brochure

FRENIC-HVAC Brochure

FRENIC-ACE Manual

FRENIC-ACE User Manual

Water Pump Flow Diagram

EVC003

PT5404

PT54xx/PU54xx Operating Instructions

Electrical panel Design

The Fuji pump panels have been designed around the needs of pumping water. Keeping the panel as simple and therefore cost effective, the panels still have the important features covering large and small water pumps. The pump panel can be fitted to various types of water pumps such as centrifugal or positive displacement pumps. Applications include irrigation pumps, bore hole pumps, cooling tower pumps, flood water pumping etc. If you cannot see the size or voltage you need, please call, or email us. Almost any kW or HP and voltage rating can be designed and built.

The panel has two modes of operation:

- Manual – motor frequency speed control

- Automatic – setpoint water pressure regulation.

Mode 1 - Manual Mode, pump speed regulation with door mounted speed potentiometer

Setting the panel in manual permits the user to start and stop with the door mounted buttons and the speed regulation directly set with the door mounted speed potentiometer. This is good when straight forward pumping is needed to move the water at a set rate. Reducing the speed of the pump may be necessary to reduce pressure or save energy. The inverter speed input can be changed to accept an external speed signal either 0-10vdc, 4-20mA or 0-20mA.

Mode 2 - Auto mode, automatic pressure regulation

A pressure setpoint can be set into the keypad and when the drive is started, the pump speed will modulate to regulate the pressure (positive acting) via the internal PID loop. Gains can be adjusted with the keypad to affect the dynamic response of the pump and optimise the water pressure.

The pump panel automatic mode can be easily changed for any process such as keeping water levels constant of a reservoir or tank with a 4-20mA sensor to measure level.

Panel Features

- Door interlocked Isolator providing local isolation for safe working.

- High-speed fuses for fault protection.

- Door mounted start & stop buttons; external remote start stop button can

be wired into double up the buttons on the door. - Door mounted potentiometer for speed control in manual.

- Door mounted keypad.

- IP54 for splash protection.

- Fuji Water pump V-F quadratic curve settings.

- High performance Energy Saving Fuji inverter with built in EMC filter.

- 4-20mA input feedback from desired sensor, pressure, flow, or process.

CUSTOM REQUEST FORM

PLEASE SUBMIT AS MUCH DETAILS AS POSSIBLE REGARDING YOUR APPLCIATION SPECIFICATIONS FOR YOUR CUSTOM PANEL

Panel Mounted Drive Keypad

The Keypad can be used to program the Fuji inverter with your motor details and display the AC motor diagnostics including frequency, pressure (when feedback device used) motor current, motor voltage. When using the panel in automatic the setpoint pressure is set using the keypad.

Motor Inverter Panel Customisation

An additional output choke or filter can be added the panel for motor cable runs that have long runs between the panel and pump. Further customisation can be done to suit your specific need and application. Please call or email us to discuss you needs and we will be happy to help.

Popular components

Fuses

Fuses act as frontline protectors in your panel, melting to interrupt dangerous current surges and safeguarding equipment.

Click here

Control Devices

Provide manual control functions (on/off, adjust settings), including push buttons, selector switches.

Click hereStock builds - call for alterations and modifications based on your needs