Lenze Inverter Drive

i500 & i700 Series Inverters

ACDC Drives can supply the i500 and i700 range of Lenze Inverters. These inverters are designed for for control panel installation and are available in IP20 and IP31 degrees of protection. For some devices, not only is the easy installation mode possible, but also the ability to use the cold-plate or push-through installation technique. The devices can be installed one after the other to save space, and they can be used in a DC bus operation, keeping the wiring efforts to a minimum. Thus, topologies can be clearly arranged even in the smallest spaces. All other control components, like the controller, the I/O system, are mounted right next to the inverters.

i500 Series

Overview

i500 is available in power ratings of 0.25kW up to 75kW. Its stand out features include streamlined design,

scalable functionality and exceptional user-friendliness.

The i500 is a quality inverter that conforms to future standards in accordance with EN 50598-2 efficiency classes

(IE). This provides a reliable and future proof drive, suited to a wide range of machine applications.

Features

- Space saving design: 60mm wide, 130mm deep with zero clearance mounting.

- Innovative interaction options allow for better set up times.

- The wide ranging modular system enables various product configurations depending on machine

requirements.

- i500 Inverters are recommended for applications such as Pumps, Fans and Conveyor, action winding, forming, tool and hoist drives.

Setup

Three set-up methods

Thanks to Lenze’s engineering philosophy, the high functionality is still easy to grasp. Parameterisation and set-up are impressive thanks to clear structure and simple dialogues, leading to the desired outcome quickly and reliably.

- Keypad: If it’s only a matter of setting a few key parameters such as acceleration and deceleration time, this can be done quickly on the keypad.

- Smart keypad app: The intuitive smartphone app enables adjustment to a simple application such as a conveyor belt.

- EASY Starter: If functions such as the motor potentiometer or sequence control for a positioning application need to be set, it’s best to use the EASY Starter engineering tool.

i700 Series

Overview

The innovative i700 servo inverter for Highlights central motion control is characterized by its compact and

highly exible design: dual axes keep the drive size to a minimum, dynamic motor control makes it suitable for use in

a wide range of applications.

Drive integration, commissioning, and maintenance are substantially simplified thanks to its installation concept

and easy engineering.

Features

- Multi-axis system

- DC-bus connection via busbar system

- Pluggable connection system

- Automatic parameter/firmware download via the control system

- Motor control

- Servo with field weakening and torque pre-control

- V/f control for standard asynchronous motors without encoder

- Scalable safety functions

- 3 cooling methods: cold plate, push- through, standard panel-mount

Automation

Controller-based automation

Powerful central motion control of demanding machine tasks is best achieved with our controller-based automation. The i700 servo inverter for multi- axis application can drive all centrally controlled motors in your machine module – from three-phase AC motor to servo motor.

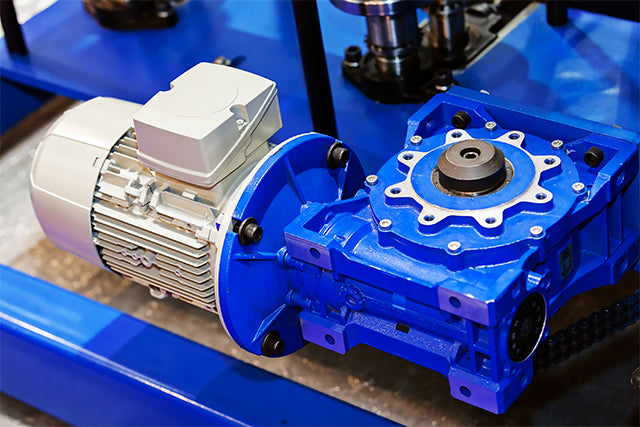

Lenze - Conveyor Systems

Horizontal or inclined motion conveyors for packaged goods need a high starting torque and gentle start-up. We can offer you simple drive solutions perfectly suited for this purpose. For constant-speed belt conveyors, our combination of the g500-B bevel gearbox and the Lenze Smart Motor gives you a compact decentralized solution that makes life easier when it comes to torque and speed transmission. And if you require variable-speed belt conveyors, the combination of the Inverter Drives 8400 motec and a g500-B bevel gearbox with a highly efficient MF three-phase AC motor provides an outstanding solution.

New freedom in motion for engineers. The Lenze Smart Motor reduces the number of different drive versions by up to 70%. This motor works without a contactor and starter, fixed speeds can be set at will and there are numerous integrated functions for material handling applications. Furthermore, the Lenze Smart Motor meets the highest requirements of energy efficiency and can be operated very conveniently using a smartphone. Advantages:

- Freely adjustable speed reduces the number of different drives

- Integrated soft start function

- Less wiring thanks to electronic contactor and motor protection function

- Outstanding energy efficiency

- Can be operated by an NFC-capable smartphone and Lenze app