Time lapse video of us testing a new electrical DC drive system at Goonhilly Earth Station. Designed, installed and commissioned by Start Electrical Services.

RETROFIT DIGITAL DC DRIVES FOR SPACE COMMS APPLICATIONS

Why did one of the world’s premier space communication gateways, Goonhilly Earth Station, choose to upgrade their deep-space satellite dish with Sprint Electric Digital DC drives rather than opting for AC alternatives?

The overall project objective was to renovate a deep space antenna to create a whole new control platform. This involved undertaking an extensive upgrade of the dish including overhauling both the radio equipment and the motor drive system.

Originally built in 1972, Antenna GHY-3 consists of a reinforced concrete tapered tower and a main 29.6m diameter counterbalanced reflector dish that is held within a

frame of interconnected and braced metal girders. There is an external lift that leads to the second floor where there is an external walkway with protective railing that leads to a brick-built support building.

As a Grade 2 listed site this landmark building is of special interest, warranting every effort to preserve its history and visual appeal.

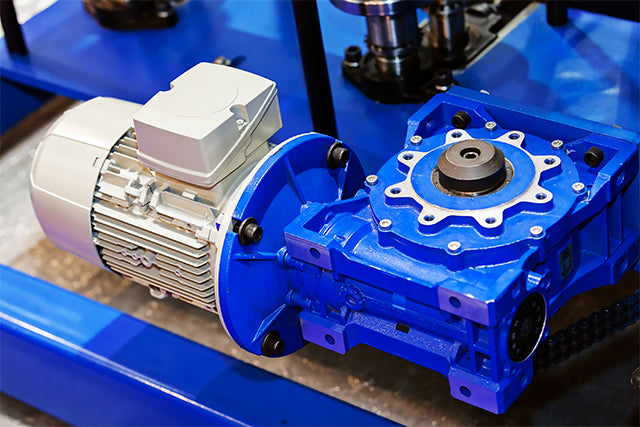

The existing motor drive system consisted of four 150Va 61Amp 1750RMP DC motors set up as:

-

Two motors on the Azimuth control driving through gearboxes mechanically linked via a drive shaft and rotating around a 6m ring on geared pinions plus

-

Two further motors on the elevation also mechanically linked via gearboxes and a line shaft driving a rack and pinion.

The mechanics of the rack and the motors were serviceable. As the existing motors were in reasonable condition there was no need to replace them.

Unfortunately, the electronic control equipment consisting of discrete rack mounted analogue control gear and a lot of interconnecting cables was found to be inoperative. This had to be removed and completely replaced with a new control system.

As the loading of the dish changed considerably over its required path of movement it was essential that the drives had both:

-

Accurate speed and current control and

-

Full four quadrant operation

Due to the intricate mechanical linking of the drive mechanism Start Electrical, who were commissioned for the whole project, decided to replace the

inoperative motion control equipment with the latest digital DC drive technology from Sprint Electric.

The specialist electrical engineers specified 4 x PLX30 72Amp 4Q Sprint Electric DC drives that allow for highly accurate current and speed control together with full four quadrant operation. This level of precision was essential in order to be able to locate and track a star or satellite at considerable distance. AC Drives do not have such a wide speed and accuracy range and so are not able to precisely control the necessary movements and so were discounted.

PLX30 72Amp 4Q Sprint Electric DC drive

The PLX digital DC drives were paired in a ‘master slave configuration’ meaning that either one of each pair is able to be the master drive. With the master drive set in speed control and the slave in current control the motors work in perfect load sharing, even though they are mechanically linked by a line shaft.

Feedback was achieved with 28 Bit Encoders giving over 26 Million pulse per revolution and allowing accuracy to be controlled to 0.001 of a degree. This precision accuracy is vital for deep space applications. The DC Drive four quadrant control ensures that this accuracy is maintained throughout the speed range and the varying load conditions.

The 4 PLX digital DC drives were controlled via PLC control with a profibus link.

A 7” touch screen relays speed and current as well as allowing for easy access to multiple fault diagnostics.

The project was completed in two phases. The Motor Control Unit, (MCU), described above and the second phase the Antenna Control Unit, (ACU), which was a joint project with Leeds University.

The flexibility of the MCU allowed the University team to maximise the adaptability of the antenna. The ACU has given the ability to locate satellites and sky objects by grid reference and then to accurately track them and this has expanded the use of Antenna GHY-3 bringing it back to life, keeping its dramatic visual quality and retaining its original form. The system far outperforms the previous control equipment.

The PL/X series DC Drive is a fully digital DC drive system providing 5kW – 980kW output power. Available in 2Q (single direction) and 4Q (fully regenerative) variants, the range comprises 5 compact chassis sizes with models rated from 12A to 2250A output current. The PL/X boasts an extremely versatile operating input voltage range of 12V – 500VAC as standard. Options are available for 600V and 690VAC input. The digital DC drives are compact and ideal for

retrofitting, please contact Sprint Electric on 01243 558080 or visit sprint- electric.com for more details.

ABOUT SPRINT ELECTRIC

Sprint Electric Ltd., based in Arundel, West Sussex and founded in 1987, offers a wide range of DC motor control, with over fifty models covering both single phase and three phase, regenerative and non-regenerative applications. From low voltage servo performance controller to highly sophisticated fully digital three phase DC variable speed drives, Sprint Electric products meet the demands of countless industrial applications around the globe. Sprint Electric is committed to providing innovative products backed up by a high level of customer service to the worldwide industrial market.

MORE INFO:

Sprint Electric Ltd.

Peregrine House, Ford, Arundel, West Sussex BN18 0DF Tel: +44 (0) 1243 558080

E-mail: info@sprint-electric.com Web: www.sprint-electric.com