Commander C300 0.25kW AC Inverter (STO) - 230VAC 1Ph Input - C300-01200017

Control Techniques

£152.47

Commander C300 - 0.37kW AC Inverter (STO) - 230VAC 1Ph Input - C300-01200024

Control Techniques

£162.55

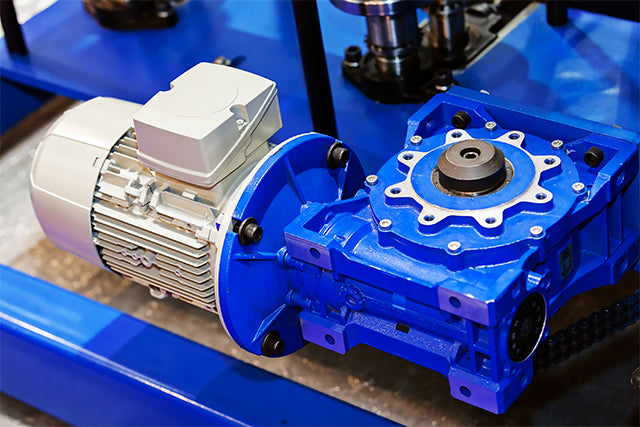

Parker AC10 Drives | Full Range In Stock

The Parker AC10 variable speed compact drive is a simple, reliable and economical solution to every-day motor control applications requiring speed or torque control within the power range of 0.2kW to 180kW. The Parker AC10 Inverter boasts compact dimensions and features typically only associated with higher specification AC drives. These include in part, sensorless vector mode, output frequency up to 590 Hz, 3 phase 400VAC supplies in all 5 frame sizes and a full 150 % overload at 0.5 Hz for 1 minute, plus many more. The Parker AC10 provides an optimised solution for OEM machine builders who are looking for a compact, cost-effective, energy-saving variable speed AC drive without compromising on performance.

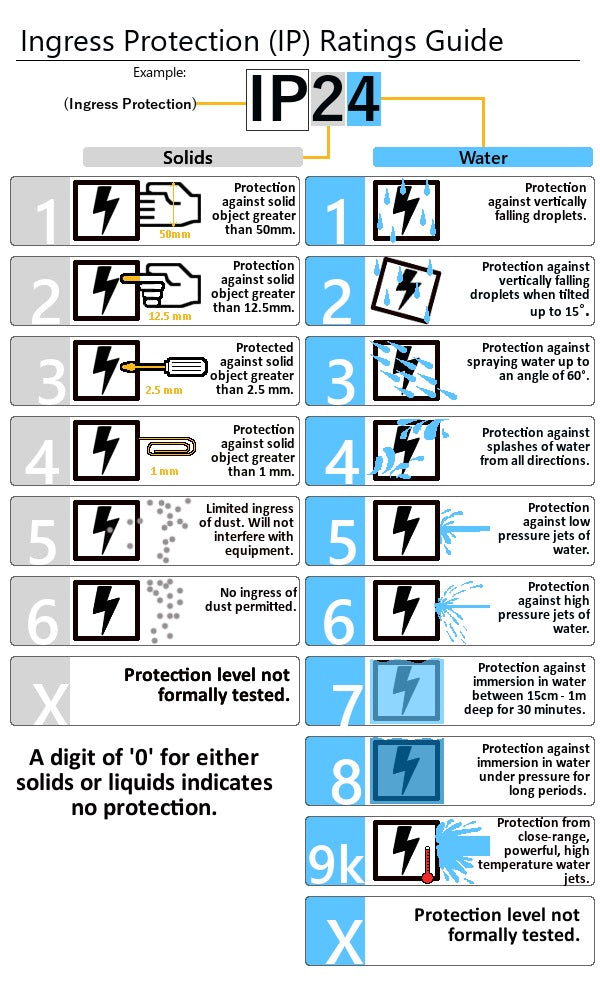

What is an IP rated Inverter?

First of all, what does IP stand for... Ingress Protection is the answer. The first number relates to the protection against solid objects, and the second digit relates to liquids. See the chart below for details.

Why use an IP20 AC10 Inverter?

The IP20 AC10 is perfect for general use inside a panel or in an environment that is relatively clean. The internal PCBs are C3C coated as standard.

Why use an IP66 AC10 Inverter?

The IP66 AC10 is dust and waterproof. These drives are suited to harsh environments, such as dusty factories, or areas that will be washed down. They are made to withstand outdoor weather and can therefore, be useful with pumps, or externally mounted directly to an application outdoors.

What Can the AC10 Inverter Do?

Can I use a Parker AC10 for a plastic extruder application?

Yes, the AC10 can provide high torque at low speeds and can be set to sensor-less vector mode. Sensorless Vector can give good speed holding and be used in recycling, blown and solid extrusion applications.

Does the Parker AC10 come with communication as standard?

The AC10 has RS485 Modbus RTU and ASCII communications as standard. It is brought out to screw terminals on the side of the inverter drive, so no special plug D-sub and so forth is needed. Setting the address is in parameter F900 and setting the baud rate is in F904.

Can the Parker AC10 save energy when running an AC motor fan?

The frequency of a 3-phase motor can be reduced too and thus the speed of the motor driving a fan or pump. Controlling the speed is much better than restricting the flow to the pump or fan and saves a considerable amount of electricity. The Parker AC10 drive can be set for the quadrating fan loading using parameter F106. This will correctly flux the motor to the application.

Does the Parker AC10 come with a PID loop?

Yes, the Parker AC10 Inverter has a built-in PID loop, this can be easily set using the Macro setup in application 5. Set F228 =5, this will set the PID up and connect the PID the, drive terminals. This PID can be used to control levels, pressures or flow using feedback on terminal AI2 as a 0-20mA,4-20mA or 0-10VDC signal from the transducer.

How far can the motor be from the Parker AC10 inverter drive?

Long distances can be troublesome due to the capacitive effect of the cables. This can be reduced by running the cables separately or putting an inductive choke or output reactor between on the output of the inverter drive. These extras can be purchased separately from ACDC Drives. Depending on the kW rating or power of the inverter drive we suggest that Parker AC10 Inverters are installed above 50 meters. Cable selection on long runs should be calculated to ensure volt drop is not excessive, and each phase cable spaced separately. EMC rated cable should be used.

Can I use a remote keypad?

Yes, a keypad can be purchased individually and can be connected using a standard CAT 5 or CAT 6 RJ45 patch lead to a socket on the inverter. The display will then be on the remote keypad along with the buttons. The lead can be up to 3 meters, any longer please use a ferrite core. The Parker keypad part number is 1001-00-00.

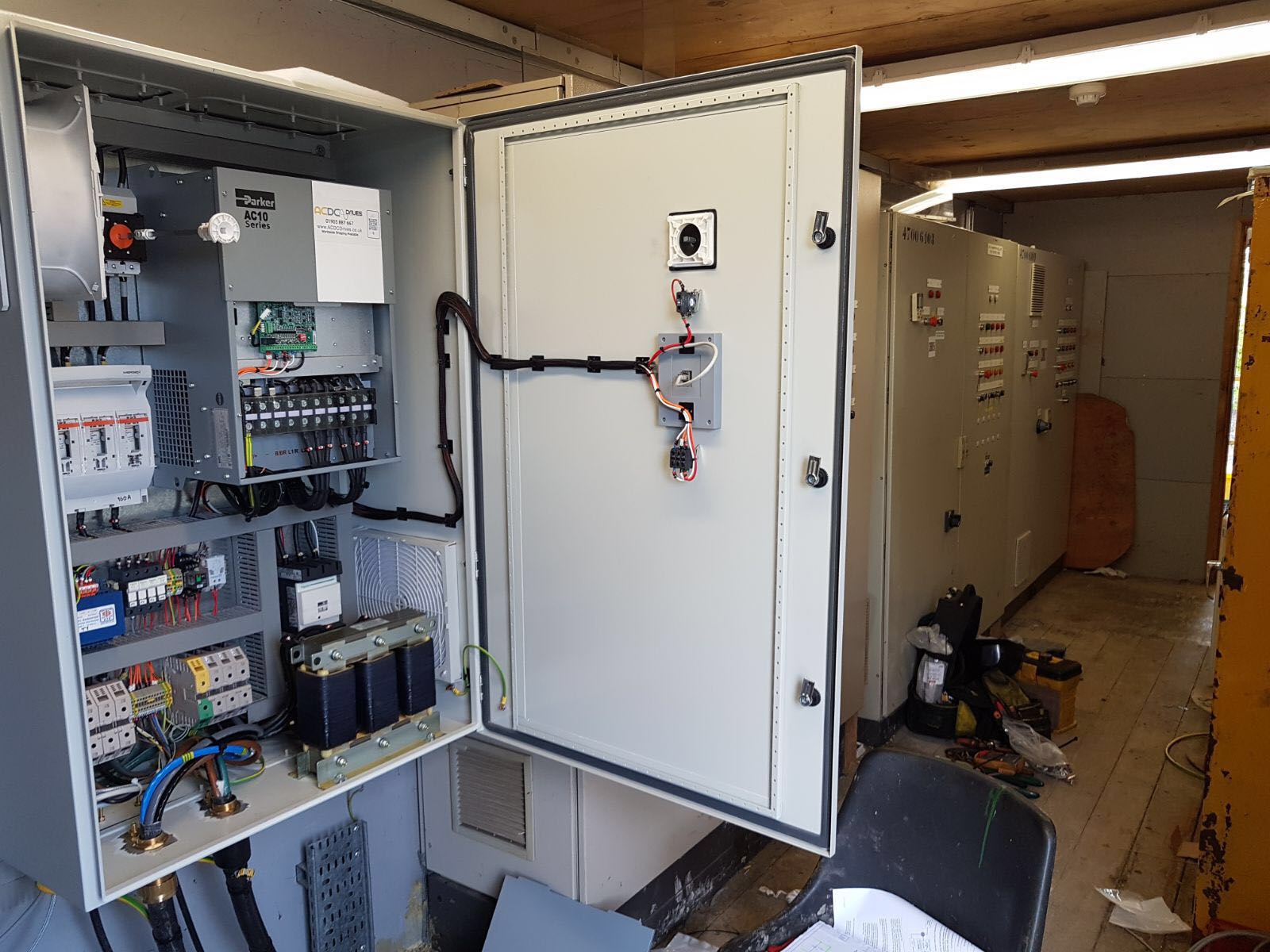

Why Buy Parker AC10 Inverters from ACDC Drives?

We use these Parker AC10 Inverters every day, so if you have any questions, ask! We all know that in the modern workplace things are often needed as quickly as possible. That is where we can help. We can also get engineers out to a site, to carry out surveys, or to install and commission drives on existing or new applications. Call our sales team today by phone on 01905 887 667.